1. Grain size Analysis

The process involves collecting a representative soil sample and gradually sieving it through a series of standardized mesh screens.

screens have varying sizes of openings, which allow only particles of certain dimensions to pass through.

The collected particles are then separated into different size fractions,

categorized as gravel, sand, silt, and clay. Each fraction represents a distinct group of particles with specific properties.

2. Plasticity Index

The Plasticity Index essentially quantifies the range of moisture content over which a soil can exhibit plastic behavior.

Soils with higher Plasticity Index values typically have greater plasticity and are more

susceptible to volume changes due to changes in moisture content. Such soils tend to experience significant swelling and shrinkage,

which can affect the stability of structures built upon them.

Plasticity Index plays a crucial role in soil classification systems like the

Unified Soil Classification System (USCS) or the American Association of State Highway and Transportation Officials (AASHTO)

classification system. Soils with different Plasticity Index values fall into different categories, aiding engineers in selecting

appropriate construction techniques and designing foundations that account for potential volume changes and load-bearing characteristics.

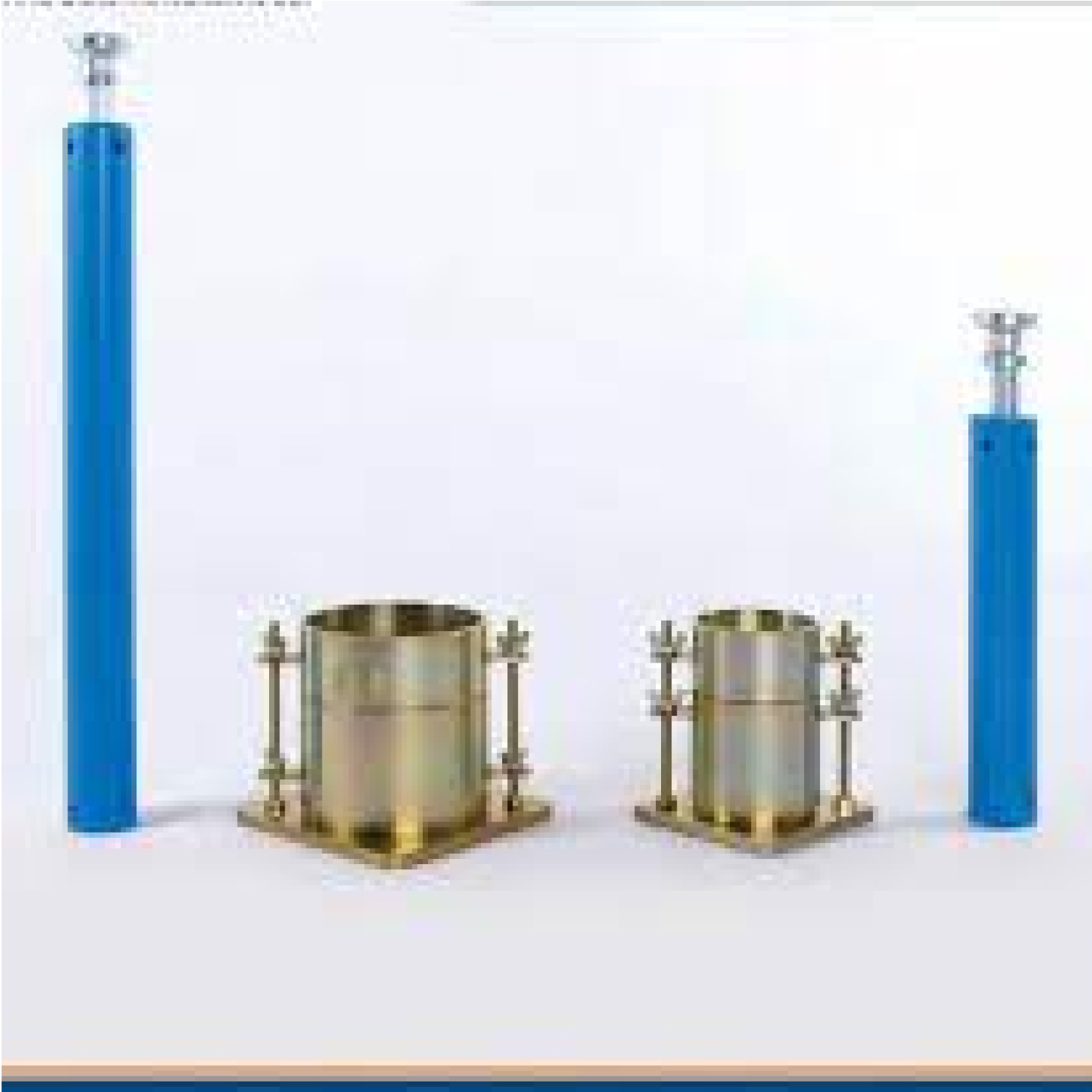

3. Light and heavy Compaction

Light compaction is typically used for less dense and granular soils, such as sands and gravels.

The equipment used for light compaction includes vibratory plate compactors, hand tampers, and pneumatic compactors.

These machines apply moderate energy to the soil surface, causing the particles to rearrange and settle, reducing air voids in the process.

Heavy compaction is employed for denser and cohesive soils, like clays and silts,

which require more energy to achieve the desired level of compaction. Equipment for heavy compaction includes vibratory rollers,

pneumatic tired rollers, and sheepsfoot rollers. These machines exert significant force on the soil, facilitating particle rearrangement and air void reduction in a more thorough manner than light compaction equipment.

4. C.B.R. Test

The California Bearing Ratio (CBR) test is a widely used laboratory test in geotechnical engineering to evaluate the mechanical strength

and load-bearing capacity of soils and granular materials. It helps assess the potential performance of these materials under varying levels of

compaction and moisture conditions. The CBR test is particularly important for designing flexible pavements, determining subgrade quality,

and making informed decisions about road construction and maintenance.

5. Direct Shear ( for soil upto 4.75mm size)

The direct shear test is a laboratory experiment used to determine the shear strength parameters of soils with particle

sizes up to 4.75mm. This test helps geotechnical engineers understand how soils respond to shear forces and

provides crucial information for designing foundations, retaining walls, slopes, and other geotechnical structures.

6.Free swell Index

The free swell index is a laboratory test used to determine the potential for certain clay

soils to undergo significant volume changes when they absorb water. This property is particularly

important in geotechnical engineering, as it can help predict the extent of swelling that a soil may experience

when exposed to moisture, which is crucial for designing foundations, slope stability, and other construction projects.

7.Swelling Pressure

Swelling pressure, also known as expansive pressure or heave pressure,

refers to the force exerted by expansive soils as they absorb water and undergo volume increase.

Expansive soils, often clay-rich in nature, have the ability to swell significantly when they absorb water and shrink when they dry out.

This behavior can exert considerable pressure on structures, foundations, and retaining walls,

potentially leading to damage or instability if not properly managed.

Swelling pressure is a critical consideration in geotechnical engineering,

particularly when designing structures in areas with expansive soils.

8.Specific Gravity

specific gravity is a valuable parameter in geotechnical engineering as it provides insights into

the behavior and characteristics of soil particles. It aids in soil classification, understanding compaction properties,

assessing porosity, and making informed engineering decisions related to foundation design, slope stability, and more.

9.Shrinkage Limit

the shrinkage limit is a fundamental property that helps engineers

understand how soils respond to changes in moisture content and provides insights into

the potential for volume changes. It plays a significant role in geotechnical engineering,

contributing to the stability and performance assessment of structures built on or with soils that undergo drying and shrinking behavior.