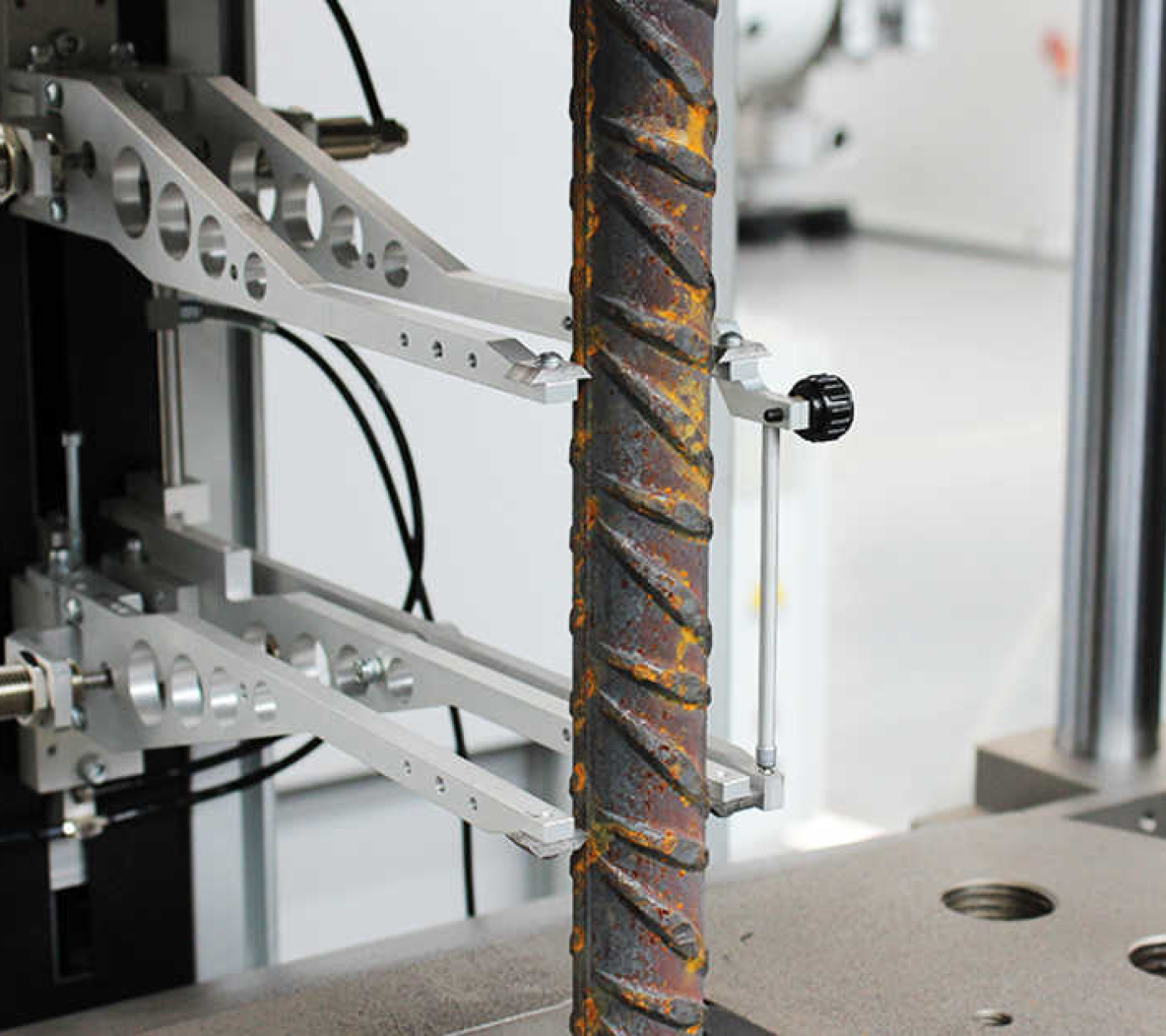

Steel testing involves a range of procedures to assess the mechanical, chemical, and physical properties of steel, a critical construction material used in various applications such as buildings, bridges, pipelines, and more. Steel testing ensures that the material meets specified standards and performance requirements, contributing to the safety, durability, and quality of structures.